For someone who is interested, I have posted the recommended tool list in the frequently asked questions portion of the site. This list for the Kit Gun Class that I am teaching this summer at WKU, but I thought it might be helpful for someone who is starting out.

Other than the gunsmithing seminar, the only event that I will be attending this summer will be the Contemporary Longrifle Association show in Lexington Kentucky this August. One table will no longer suffice, so we will set up in a booth along the wall by Ron Scott in the same room that I am normally in. I will have some examples of kits at various stages of completion available to look at and in a variety of finishes. I have addressed some other questions on the FAQ page for kit guns and will add to that as more questions come. As always, feel free to give me a call at 330-223-1775 or my cell at 330-341-0675 or shoot me an email jim@kiblerslongrifles.com. Thanks, Jim

Comments

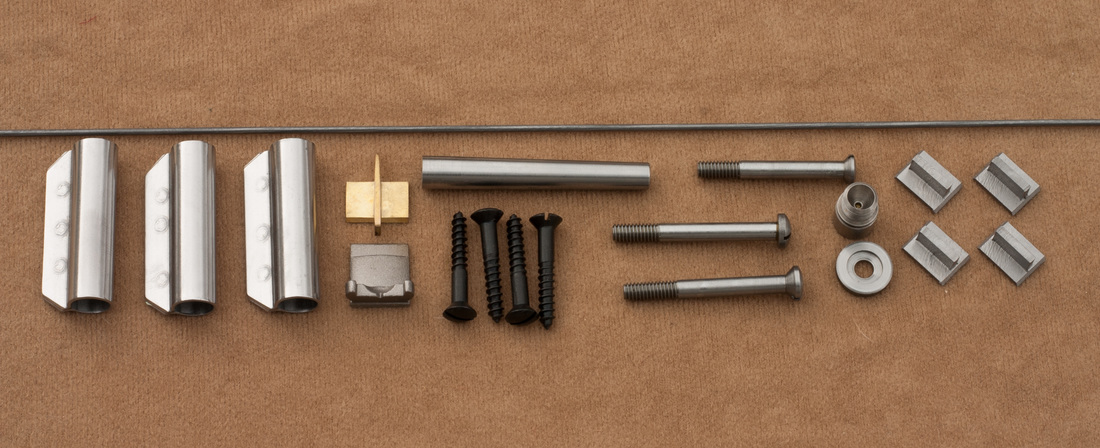

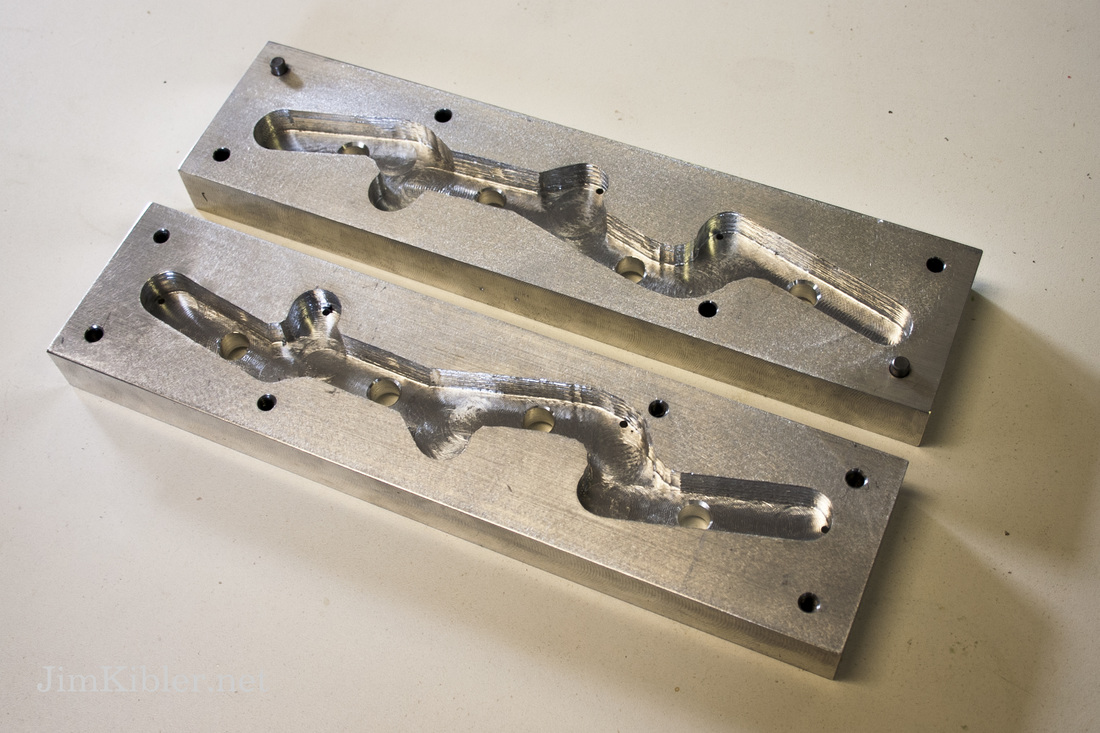

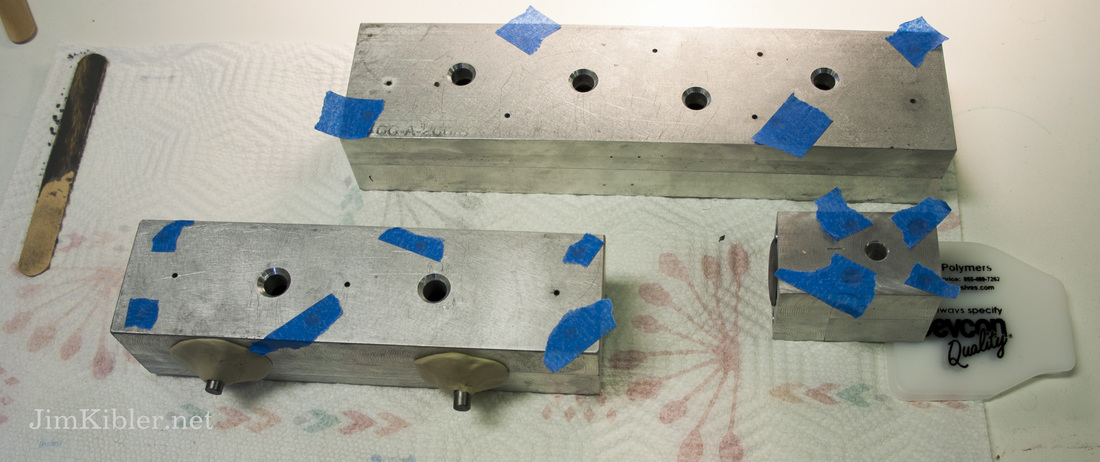

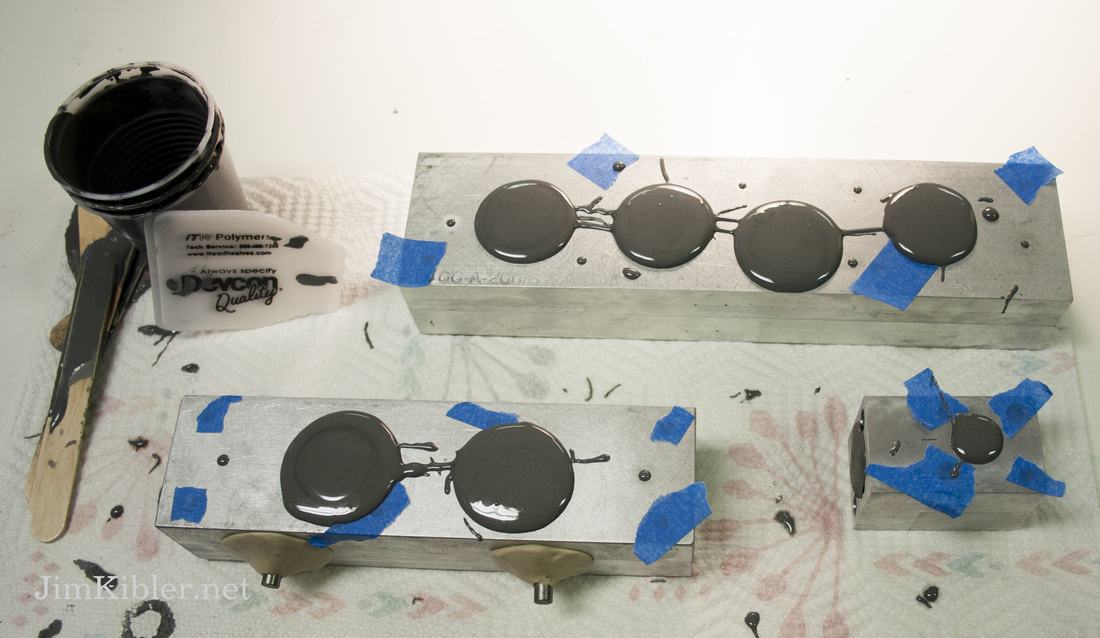

Home StretchI have been working very hard and making good progress over the last month to pull all of the remaining loose ends together on the Southern Mountain Rifle Kit. Since this is a project several years in development, I'm very happy to finally be able to begin production of these kits. All systems are nearly in place. Making Aluminum Molds for Investment CastingIn order to make large numbers of precise investment castings, aluminum shelled, epoxy filled molds have been made. These take considerable time to make but are a requirement. A quick overview is as follows: Molds must be designed such that the injected wax can be removed. All pieces are dowel pinned together for repeatable alignment. Oversize cavities are cut to accept the master. The master is then orientated properly in the mold and half is carefully bedded in putty. The remaining part of the mold is placed over the part and epoxy is poured through previously drilled holes. After curing, the mold is opened up, putty is removed, the mold is re-assembled and the remaining portion of the mold is poured.

Cutting out Stock BlanksBefore Christmas, Katherine and I made a trip to Pennsylvania for some lumber. This place was in the mountains surrounded by lots of timber and had a great selection. Katherine and I went through every board that met the minimum size standards to hand select for quality and figure. We came away very happy with what we will be able to offer for kits. We loaded up the truck and hauled it home and the next day were lucky with some nice weather for blanking it out. To keep the dust out of the shop, I rolled the bandsaw out into the drive way.

Now, we have stocks blanked out and are now able to offer a double upgrade for extra fancy maple for $150. If I were selling these blanks separately, I would be charging much more for them, but I want to be able to offer beautiful wood as part of the kit. We worked into the early evening. Frequently Asked Questions A lot of phone calls I have been getting have revolved around whether or not this is something a beginner can do. It absolutely is. This is by far the easiest kit out there and I have been making sure, every step of the way, that I am doing as much of the work as possible to keep it simple and straightforward for the buyer. Also, I am only a phone call or email away if someone does run into questions. Also, I will include some general instructions in the kit in order to help get you on the right track. There has been a fantastic response regarding the kit gun project and I am so appreciative of all of the support that I have received. I have taken a lot of orders. As of today, the expected delivery of new orders is early May. Some people have been concerned about the length of the rifle. Although it is 46", it is a swamped barrel which flares at the ends and it is nicely balanced and handles well. I have addressed some other questions on the FAQ page for kit guns and will add to that as more questions come. Kit Gun Locks Sold Through Flintlocks, LLCAll of the Chambers locks for the kits will now be purchased through a separate company, Flintlocks, LLC. This company is in house so the lock will be able to be shipped together with the rest of the kit but will be invoiced separately and payment will need to be directed to Flintlocks, LLC. The website will be updated with this new information shortly. I am very excited to be so close to this project being complete and shipping the kits next month. As always, feel free to give me a call at 330-223-1775 or my cell at 330-341-0675 or shoot me an email jim@kiblerslongrifles.com.

Thanks, Jim Hey there everyone. I thought I would take a bit of time and introduce you to a project I am working on... A mountain rifle kit. These kits will be significantly different than any others offered today. Instead of stocks being produced on pantograph type duplicating machines, CNC technology will be used. These kits will combine both excellent design and precise manufacturing. The stocks and hardware will be produced in my shop, the locks will be provided by Jim Chambers and the barrels will be provided by Rice. The design of this kit is somewhat based on the work of Whitson from Western North Carolina (refer to photo included). Rifles will be iron mounted and have 46" swamped barrels available in 32, 36, and 40 calibers. Jim Chambers late Ketland locks will be used. As noted previously, the most significant feature of these kits is the method stock are produced. With CNC, very precise and repeatable results can be obtained. Inlets are clean and precise and in proper location relative to each other. All parts are inlet and require very little fitting. The barrel will come fit to the stock. All holes (bolt and pin) will be drilled. Stock surfaces are extraordinarily refined with little to no extra material. What this all results in is a product that has excellent design and style that can be assembled quickly and easily with little hassle. Additional features of these rifles include tangs fully shaped tangs that extend down the length of the wrist, nicely designed iron hardware and custom set triggers designed specifically for this project. These will come fitted in custom fitted packaging to provide secure shipment. Kits will likely be ready for shipment sometime late this winter. Estimated time for assembly and finishing is 3-4 days for someone with little experience. Those more skilled might complete assemble in as little as 1-2 days. Guns can of course be customized to make them unique. Grease holes can be cut, a box could be added, a decorative nose cap could be poured or perhaps a silver name plate could be installed. A perfect project for those interested in a fine squirrel rifle! A course on assembling these kits is being offered at this years Gunsmithing Seminar at WKU. Check out the following link for more details: http://www.nmlragunsmithingseminar.org/ Below are some photos of a the partially completed project. These should provide an idea of what to expect. (sorry for the marginal photo quality, I'll try to add some better ones in time) NOTE: THE STOCK IS NOT COMPLETE, MORE DEVELOPMENT IS REQUIRED FOR ADDITIONAL INLETS SUCH AS THE FULL LENGTH TANG, TRIGGERS, GUARD AND SIDEPLATE. THESE WILL BE INCLUDED WHEN KITS ARE AVAILABLE FOR PURCHASE. I am taking pre-orders. Based on early response, I expect the first batch to go pretty quickly. Price of complete kit will be introduced at $950. This will include all the parts necessary to complete rifle. A nice quality figured maple or walnut stock can be chosen. Calibers will be your choice of 32 or 36 or 40. To pre-order I would like 25% of the cost down and the remainder upon shipment. They can be purchased through the Kibler's Longrifles store on this website with a credit card, or through a check or money order. If you have any interest, please contact me at kiblerjr@frontier.com (or any of my other addresses you might have) You can also give me a call at 330-223-1775 Any questions or comments just ask! Let me know what you think! Thanks, Jim Kibler Kibler's Longrifles Hey there everyone. Time for another post... In this segment, I'll show some of the steps used to make a steel thumb piece for the fowling piece I've been working on. Steel hardware with carved relief can be produced by forming the part and chiseling or by investment casting. Both methods have their merits and drawbacks. In the case of the thumb piece being discussed, I chose to carve a master and investment cast the steel part. After casting, it was cleaned up with gravers, rifflers and polishing stones. The master thumb piece was carved out of high density polyurethane modeling board. The stuff I used was sold under the name "Butter board". It carves well and is a pretty nice material to use.

The as-cast surface finish was pretty decent, but still required significant attention to clean up well. In this case I used a combination of riffler files and polishing stones. Gravers were used to add details not included in the casting. This isn't a fast process, but is required to make a cast piece look as good as it can and to emulate a chiseled piece. Finally the thumb piece was inlet into the stock. I realize this wasn't a highly detailed summary, so if you have any questions at all, don't hesitate to ask. I enjoy the feedback. I'd also like to thank everyone for the positive response concerning these blog posts. They take a bit of time and I always seem to be behind with my gun work, but I enjoy sharing a little bit of what I've been working on.

The burl stocked fowling piece will be completed soon. Basically some lock work and engraving left. I'd like to mention that I've built this as a "spec" piece and that it isn't sold. So if you should have an interest, let me know. I'm not certain what I will need for it at this point. I would like to make a final decision after the entire project is complete. It will be nice when it's done and move onto the next one! Thanks, Jim |

AuthorJim Kibler--maker of flintlock rifles. Archives

May 2019

Categories

All

|

Kibler's Longrifles

HoursM-F: 8am - 6pm

|

Telephone |

|

RSS Feed

RSS Feed