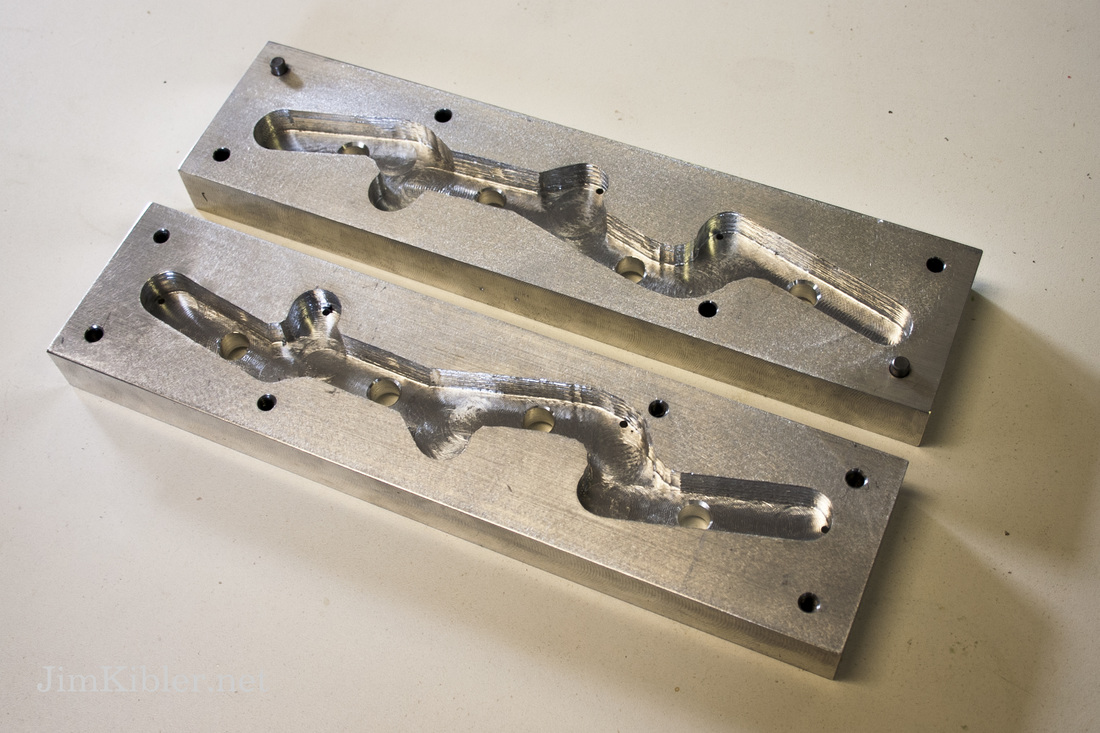

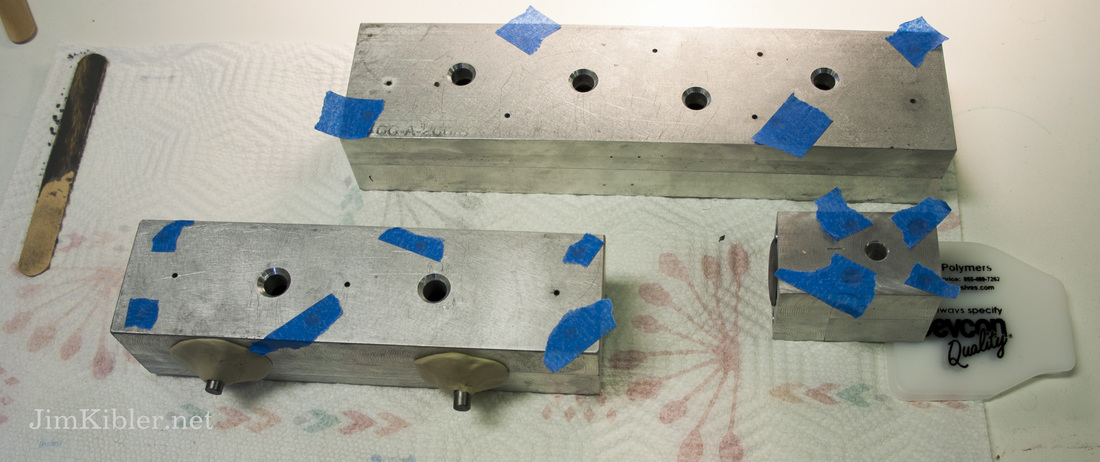

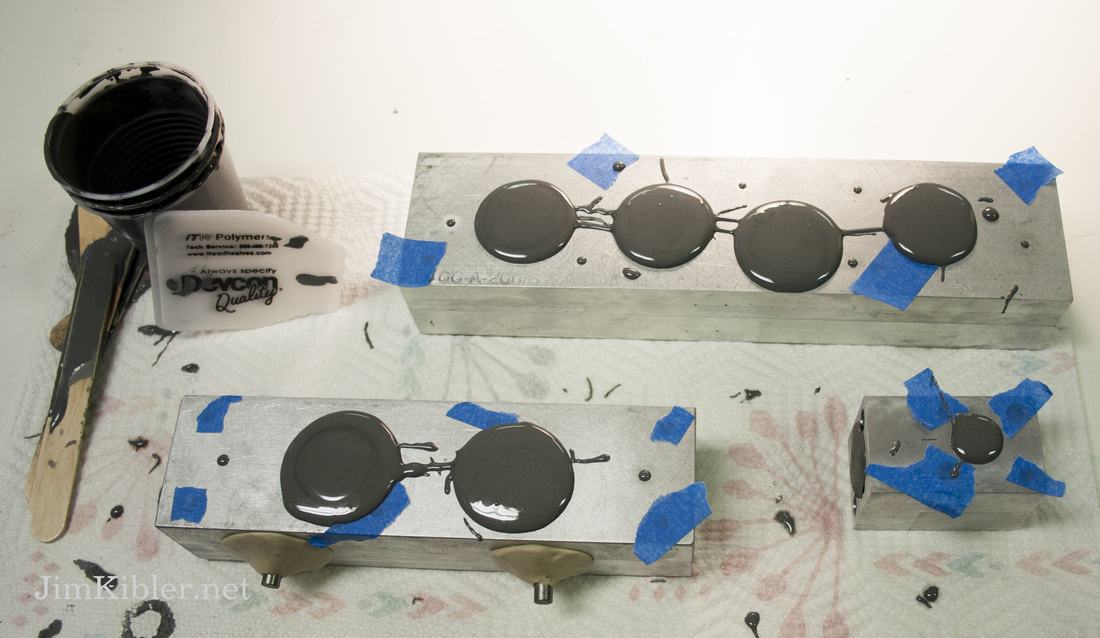

Home StretchI have been working very hard and making good progress over the last month to pull all of the remaining loose ends together on the Southern Mountain Rifle Kit. Since this is a project several years in development, I'm very happy to finally be able to begin production of these kits. All systems are nearly in place. Making Aluminum Molds for Investment CastingIn order to make large numbers of precise investment castings, aluminum shelled, epoxy filled molds have been made. These take considerable time to make but are a requirement. A quick overview is as follows: Molds must be designed such that the injected wax can be removed. All pieces are dowel pinned together for repeatable alignment. Oversize cavities are cut to accept the master. The master is then orientated properly in the mold and half is carefully bedded in putty. The remaining part of the mold is placed over the part and epoxy is poured through previously drilled holes. After curing, the mold is opened up, putty is removed, the mold is re-assembled and the remaining portion of the mold is poured.

Cutting out Stock BlanksBefore Christmas, Katherine and I made a trip to Pennsylvania for some lumber. This place was in the mountains surrounded by lots of timber and had a great selection. Katherine and I went through every board that met the minimum size standards to hand select for quality and figure. We came away very happy with what we will be able to offer for kits. We loaded up the truck and hauled it home and the next day were lucky with some nice weather for blanking it out. To keep the dust out of the shop, I rolled the bandsaw out into the drive way.

Now, we have stocks blanked out and are now able to offer a double upgrade for extra fancy maple for $150. If I were selling these blanks separately, I would be charging much more for them, but I want to be able to offer beautiful wood as part of the kit. We worked into the early evening. Frequently Asked Questions A lot of phone calls I have been getting have revolved around whether or not this is something a beginner can do. It absolutely is. This is by far the easiest kit out there and I have been making sure, every step of the way, that I am doing as much of the work as possible to keep it simple and straightforward for the buyer. Also, I am only a phone call or email away if someone does run into questions. Also, I will include some general instructions in the kit in order to help get you on the right track. There has been a fantastic response regarding the kit gun project and I am so appreciative of all of the support that I have received. I have taken a lot of orders. As of today, the expected delivery of new orders is early May. Some people have been concerned about the length of the rifle. Although it is 46", it is a swamped barrel which flares at the ends and it is nicely balanced and handles well. I have addressed some other questions on the FAQ page for kit guns and will add to that as more questions come. Kit Gun Locks Sold Through Flintlocks, LLCAll of the Chambers locks for the kits will now be purchased through a separate company, Flintlocks, LLC. This company is in house so the lock will be able to be shipped together with the rest of the kit but will be invoiced separately and payment will need to be directed to Flintlocks, LLC. The website will be updated with this new information shortly. I am very excited to be so close to this project being complete and shipping the kits next month. As always, feel free to give me a call at 330-223-1775 or my cell at 330-341-0675 or shoot me an email jim@kiblerslongrifles.com.

Thanks, Jim

Comments

Hello Everyone. As promised, I will be posting periodically to my blog. So here it goes... For the last while I've been building a late 17th century or early 18th century fowling piece stocked in burl maple. Burl maple was quite fashionable for gunstocks from around 1670 until 1710 or so. It is fairly rare wood and somewhat difficult to work. It's prone to having a lot of defects, voids etc, but it's beauty is unmatched in my view. For a little more information on burl, check out this article on wood technology that Gary Brumfield put together: I have experimented quite a bit with finishing in order to try to bring out the most figure. I've tried dyes, ferric nitrate (aquafortis) etc. but never seemed to get the results I was hoping for. Many burl stocked original guns I've examined have been finished in a manner to create dramatic contrast in the wood figure (see the Cookson fowling piece and Italian carbine shown in the "Originals" tab). For some time I've heard about the use of tannic acid to accentuate maple figure. This is used in conjunction with ferric or iron nitrate in the staining process. In practice a solution of tannic acid in water is prepared and applied to the bare stock. After this dries, the iron nitrate is applied. A reaction between the iron nitrate and tannic acid occurs forming an iron tannate compound which is very dark in color. After this step, the entire stock is quite dark. Next comes abrading the stock to work the stain off the long grain wood to bring out the figure. This process relies in the varying grain direction of burl wood. The stain can be fairly easily removed from the long grain regions, but is quite permanent in the end grain areas since the stain is absorbed pretty deeply. I found it best to use a combination of fine sand paper and woven abrasive Scotch-Brite pads. It was also helpful to use oil or finish during this process, to keep the abrasives from becoming plugged and to evaluate the progress. !After the stock was worked back sufficiently, I applied stock finish mixed with a warm amber colored aniline dye to give a slight color to the long grain regions of the wood. After a bit more finishing here is how the stock looks. Pretty dramatic if I say so myself! On a final note, If you would like to receive an email notification when additions to this blog are posted, please sign up!

If anyone has any questions or comments I'd love to hear from you. Jim |

AuthorJim Kibler--maker of flintlock rifles. Archives

May 2019

Categories

All

|

Kibler's Longrifles

HoursM-F: 8am - 6pm

|

Telephone |

|

RSS Feed

RSS Feed